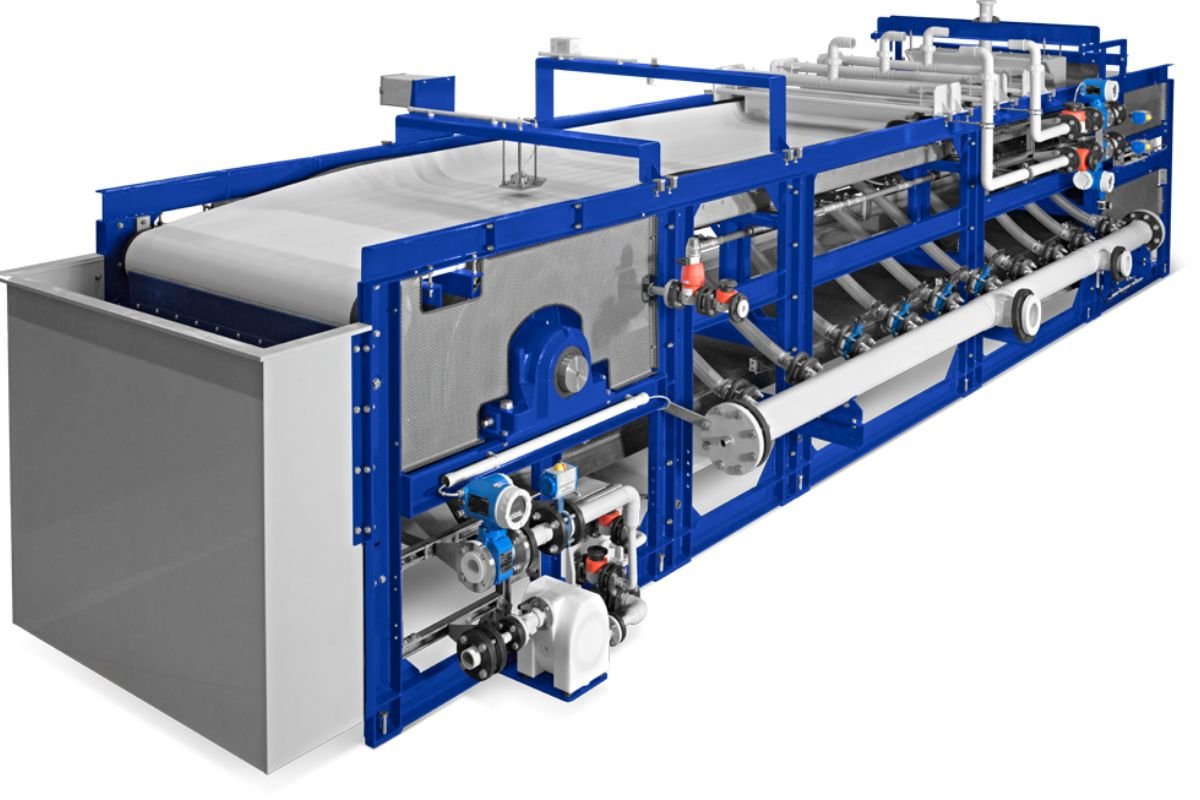

The Horizontal Vacuum Belt Filter (HVBF) is a highly efficient, continuous filtration system used for solid-liquid separation in various industries. Its design features a moving filter belt that allows for effective dewatering, washing, and separation of fine particles from liquids. With its horizontal configuration, the HVBF ensures uniform cake formation, making it an excellent choice for applications that require high throughput and consistent performance.

This filtration system operates under vacuum pressure, drawing liquid through the belt while leaving behind a solid cake that can be further processed or discarded. HVBFs are widely used in industries such as mining, chemical processing, food & beverage, and wastewater treatment due to their reliability, versatility, and low operational costs.

How It Works

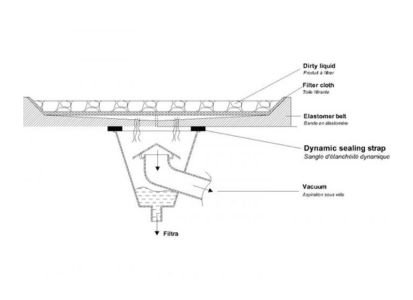

The Horizontal Vacuum Belt Filter operates on a continuous cycle, where the slurry is evenly distributed across a moving filter belt. As the belt moves forward, a vacuum system generates suction underneath, pulling the liquid through the belt while leaving the solid particles behind to form a filter cake. This process ensures efficient separation and allows for easy recovery of valuable materials.

In many cases, an integrated washing section sprays liquid onto the cake to remove impurities or recover additional product before the solid cake is discharged. Rollers and drive systems keep the belt moving at a controlled speed, ensuring smooth operation and maintaining consistent filtration performance. The result is a highly efficient separation process with minimal energy consumption and low maintenance requirements.

Key Features & Advantages

High Efficiency

The continuous filtration process ensures high throughput with minimal downtime.

Consistent Filtration

The horizontal orientation ensures uniform cake formation and consistent separation of solids and liquids.

Low Energy Consumption

The design minimizes energy usage while maintaining excellent filtration efficiency.

Ease of Maintenance

Designed for easy operation and maintenance, reducing downtime and operational costs.

Applications

- Mining Processing

- Chemical Industry

- Food & Beverage

- Wastewater Treatment

- Pharmaceuticals

- Mineral Processing

Why Choose a HVBF ?

The HVBF stands out for its ability to handle large volumes with high efficiency and reliability. Its design ensures a continuous process with minimal operator intervention, making it an ideal choice for industries that demand consistent filtration performance. With low energy consumption, easy maintenance, and a versatile range of applications, the HVBF is a cost-effective and dependable solution for solid-liquid separation.

Frequently asked questions

HVBFs are widely used in industries such as mining and mineral processing, chemical manufacturing, food and beverage processing, wastewater treatment, and pharmaceuticals. They are ideal for applications requiring continuous solid-liquid separation, dewatering, and cake washing.

The HVBF operates on a continuous cycle, allowing for uninterrupted filtration, high throughput, and minimal downtime. Its vacuum-driven system enhances liquid removal, while the horizontal design ensures uniform cake formation, leading to consistent and efficient filtration.

HVBFs can handle a wide range of slurries, including fine chemical sludges, mineral concentrates, food and beverage waste, pharmaceutical compounds, and industrial wastewater solids. The filter belt material can be customized based on the specific filtration requirements.

HVBFs are designed for ease of maintenance. Regular inspection and cleaning of the filter belt, vacuum system, rollers, and discharge mechanisms help ensure smooth operation. Since the system is continuous, maintenance can often be scheduled without significant downtime.

Yes, HVBFs can be customized based on process requirements, including belt material, filtration area size, washing stages, and vacuum pressure levels. This flexibility allows them to be adapted for various industrial applications.