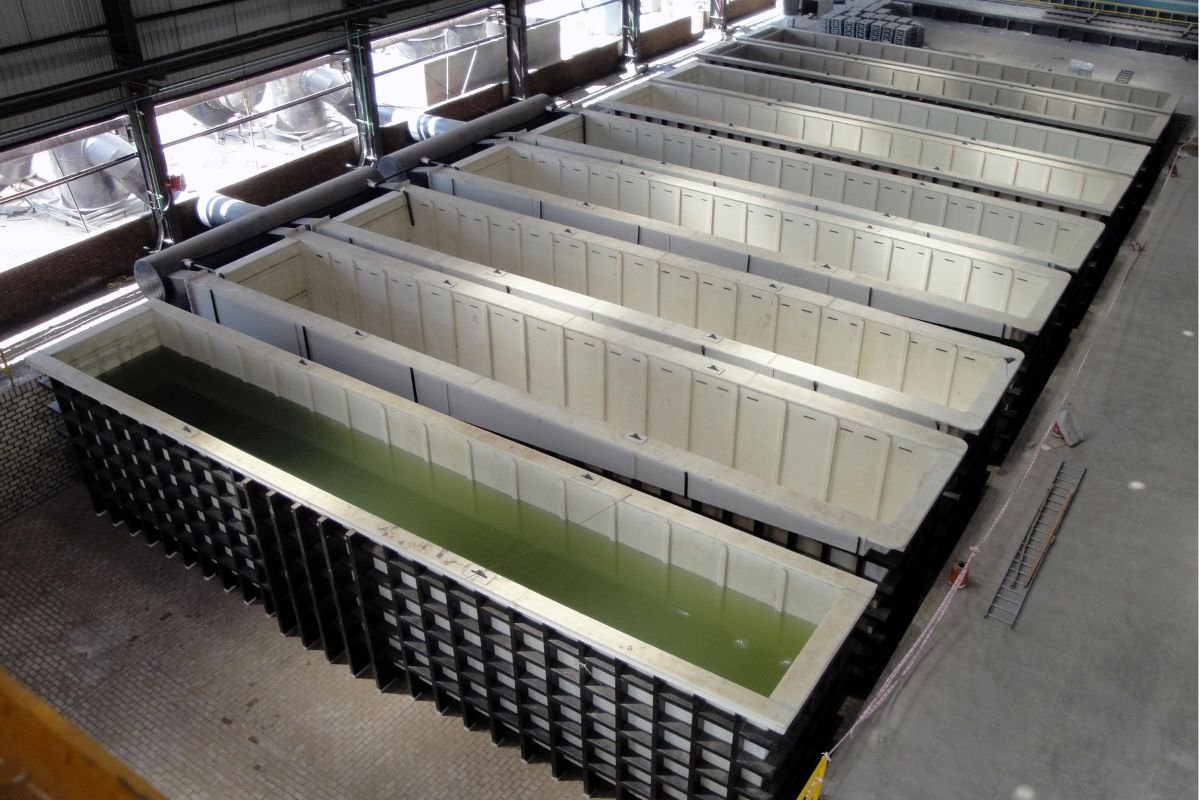

Pickling Tanks are specialized containers designed for the pickling process, which involves the removal of impurities, oxides, and scale from metal surfaces using acidic solutions. These tanks are constructed from materials that resist corrosion, such as polypropylene (PP), fiberglass-reinforced plastic (FRP), or stainless steel, ensuring durability and longevity in harsh chemical environments.

Pickling Tanks are widely used in industries such as metal fabrication, automotive, and aerospace, where surface preparation is critical for further processing. Their robust design and chemical resistance make them ideal for handling aggressive acids and ensuring consistent, high-quality results in the pickling process.

How It Works

Pickling Tanks are filled with acidic solutions, such as hydrochloric acid or sulfuric acid, which are used to remove surface impurities from metal parts. The metal components are submerged in the tank for a specific duration, allowing the acid to dissolve oxides, rust, and scale. The process ensures a clean and smooth surface, ready for further treatment or coating.

The tanks are equipped with features such as ventilation systems, drainage outlets, and safety mechanisms to handle the corrosive nature of the pickling solution. After the pickling process, the metal parts are rinsed and neutralized to remove any residual acid, ensuring a safe and clean finish.

Key Features & Advantages

Corrosion Resistance

Constructed from materials like PP, FRP, or stainless steel, Pickling Tanks are highly resistant to corrosive acids, ensuring long-term durability.

Customizable Design

Pickling Tanks can be tailored to specific requirements, including size, shape, and additional features like ventilation and drainage systems.

Safety Features

Equipped with ventilation systems, drainage outlets, and safety mechanisms to handle corrosive solutions safely.

Efficient Process

Ensures consistent and high-quality surface preparation, making it ideal for industries requiring precise metal treatment.

Applications

- Metal Fabrication

- Automotive Industry

- Aerospace Industry

- Steel Manufacturing

- Surface Treatment

- Industrial Cleaning

Why Choose Pickling Tanks?

Pickling Tanks are the ideal choice for industries requiring efficient and reliable surface preparation of metal components. Their corrosion-resistant construction, customizable design, and safety features ensure optimal performance in handling aggressive acids. With their ability to deliver consistent and high-quality results, Pickling Tanks provide a cost-effective solution for metal treatment and surface cleaning processes.

Frequently Asked Questions

Pickling Tanks are typically made from corrosion-resistant materials such as polypropylene (PP), fiberglass-reinforced plastic (FRP), or stainless steel.

Yes, Pickling Tanks are designed to handle a variety of acids, including hydrochloric acid and sulfuric acid, depending on the material of construction.

Yes, Pickling Tanks are equipped with safety features such as ventilation systems and drainage outlets to ensure safe handling of corrosive solutions.

Yes, Pickling Tanks can be customized in terms of size, shape, and additional features to meet specific industrial requirements.

Pickling Tanks are widely used in industries such as metal fabrication, automotive, aerospace, steel manufacturing, and surface treatment.