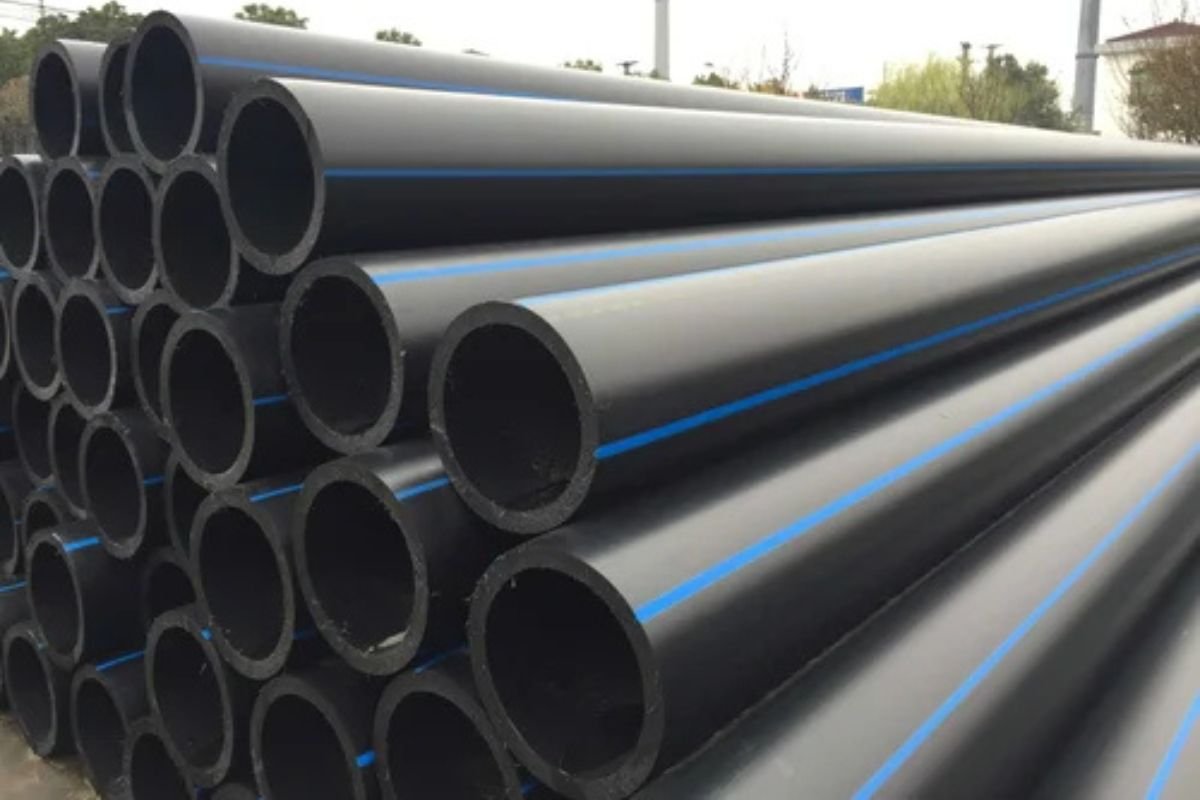

HDPE (High-Density Polyethylene) Pipes are widely used in various industries for their durability, flexibility, and resistance to corrosion and chemicals. Made from high-quality polyethylene material, these pipes are ideal for transporting water, chemicals, gases, and other fluids in demanding environments. Their lightweight design and ease of installation make them a preferred choice for both above-ground and underground applications.

HDPE Pipes are known for their long service life, low maintenance requirements, and ability to withstand high pressure and temperature variations. They are commonly used in water supply systems, irrigation, industrial pipelines, and gas distribution networks. With their excellent performance and cost-effectiveness, HDPE Pipes provide a reliable solution for fluid transportation needs.

How It Works

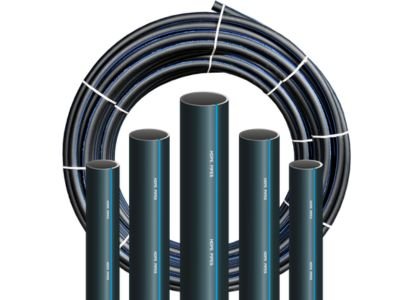

HDPE Pipes are manufactured using extrusion technology, where polyethylene resin is melted and formed into a continuous pipe shape. The pipes are then cooled and cut to the required lengths. The seamless construction ensures leak-proof performance and high strength, making them suitable for high-pressure applications.

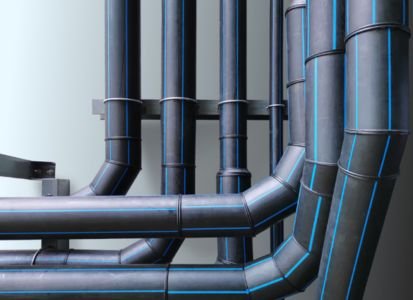

HDPE Pipes are joined using heat fusion techniques, such as butt welding or electrofusion, which create strong, leak-proof connections. This eliminates the need for additional fittings and ensures a smooth flow of fluids. The pipes are resistant to abrasion, chemicals, and UV radiation, making them suitable for both indoor and outdoor installations.

Key Features & Advantages

Durability

HDPE Pipes are highly resistant to corrosion, abrasion, and chemical damage, ensuring a long service life even in harsh environments.

Flexibility

The flexibility of HDPE Pipes allows them to withstand ground movements and pressure variations without cracking or breaking.

Leak-Proof

Heat fusion techniques create seamless, leak-proof joints, ensuring a smooth and uninterrupted flow of fluids.

Cost-Effective

HDPE Pipes offer a low-cost solution for fluid transportation due to their long lifespan, low maintenance, and ease of installation.

Applications

- Water Supply Systems

- Irrigation and Agriculture

- Industrial Pipelines

- Gas Distribution Networks

- Wastewater Treatment

- Mining and Slurry Transport

Why Choose HDPE Pipes?

HDPE Pipes are the ideal choice for industries requiring durable, flexible, and cost-effective fluid transportation solutions. Their resistance to corrosion, chemicals, and UV radiation ensures reliable performance in various environments. With their leak-proof design, ease of installation, and long service life, HDPE Pipes provide a sustainable and efficient solution for water, gas, and industrial applications.

Frequently Asked Questions

HDPE Pipes can last for over 50 years, depending on the application and environmental conditions, due to their high durability and resistance to corrosion.

Yes, HDPE Pipes are designed to withstand high-pressure applications, making them suitable for water supply, gas distribution, and industrial pipelines.

Yes, HDPE Pipes are highly suitable for underground installation due to their flexibility, resistance to ground movements, and long-term durability.

HDPE Pipes are joined using heat fusion techniques, such as butt welding or electrofusion, which create strong, leak-proof connections.

Yes, HDPE Pipes are safe for transporting drinking water as they are non-toxic, corrosion-resistant, and meet international standards for potable water systems.