PP FRP (Polypropylene Fiber Reinforced Plastic) Blowers are highly durable and corrosion-resistant air movement solutions designed for industries requiring reliable and efficient ventilation. Made from a combination of polypropylene and fiberglass, these blowers offer exceptional resistance to chemicals, moisture, and UV radiation, making them ideal for harsh industrial environments.

PP FRP Blowers are widely used in chemical processing, wastewater treatment, and other industries where corrosive fumes and gases are present. Their lightweight construction, low maintenance requirements, and long service life make them a cost-effective solution for air handling and ventilation needs.

How It Works

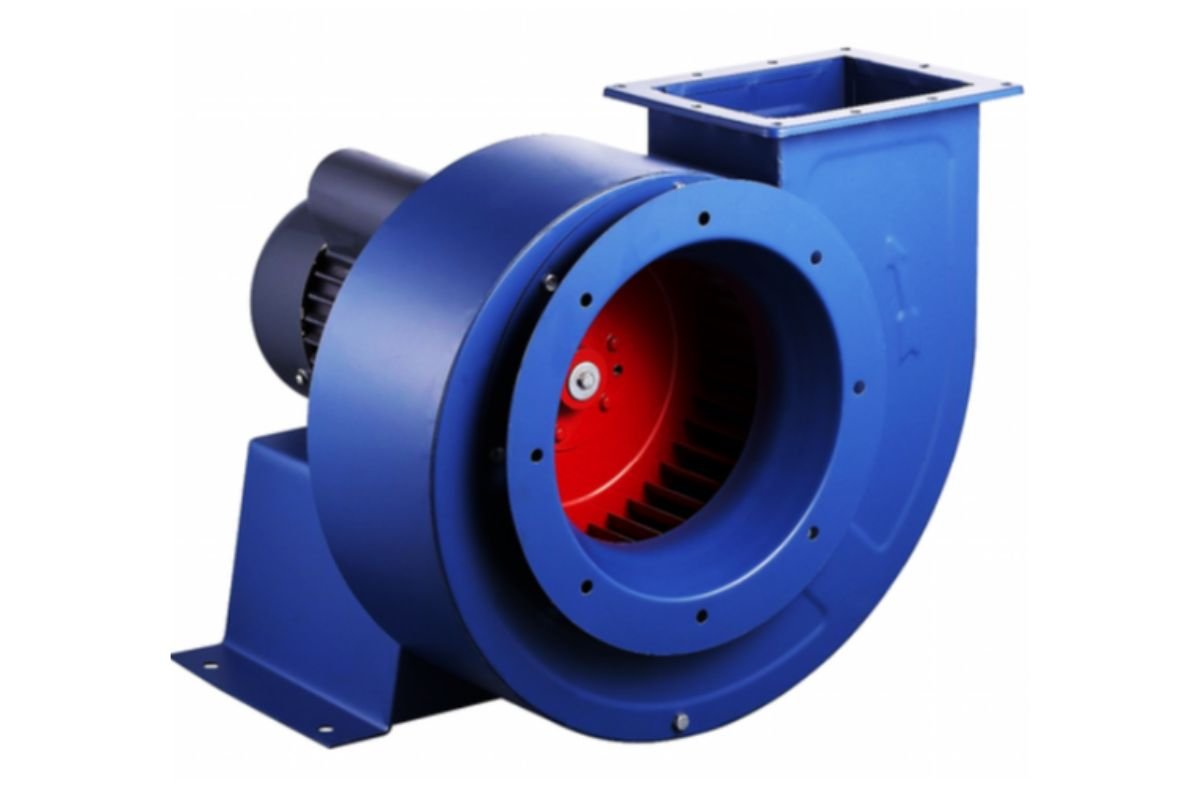

PP FRP Blowers operate by drawing in air or gases and expelling them at high pressure using an impeller system. The blowers are designed with corrosion-resistant materials, ensuring reliable performance in environments with aggressive chemicals and high humidity. The impeller is balanced for smooth operation, reducing noise and vibration.

The blowers are equipped with motors and control systems that allow for adjustable airflow and pressure settings. Their robust design ensures minimal wear and tear, even in continuous operation. PP FRP Blowers are suitable for both indoor and outdoor installations, providing efficient ventilation in challenging environments.

Key Features & Advantages

Corrosion Resistance

PP FRP Blowers are highly resistant to corrosive chemicals, moisture, and UV radiation, ensuring long-term durability.

High Efficiency

Designed for optimal airflow and pressure, PP FRP Blowers provide efficient ventilation with minimal energy consumption.

Low Maintenance

The robust design and corrosion-resistant materials reduce the need for frequent maintenance, lowering operational costs.

Versatility

Suitable for a wide range of applications, including chemical processing, wastewater treatment, and industrial ventilation.

Applications

- Chemical Processing

- Wastewater Treatment

- Industrial Ventilation

- Air Pollution Control

- HVAC Systems

- Fume Extraction

Why Choose PP FRP Blowers?

PP FRP Blowers are the ideal choice for industries requiring durable, corrosion-resistant, and efficient air movement solutions. Their ability to withstand harsh environments, combined with their low maintenance requirements and high efficiency, ensures reliable performance in critical applications. With their versatility and long service life, PP FRP Blowers provide a cost-effective solution for ventilation and air handling needs.

Frequently Asked Questions

PP FRP Blowers are made from a combination of polypropylene and fiberglass, ensuring high corrosion resistance and durability.

Yes, PP FRP Blowers are designed to handle corrosive gases and fumes, making them ideal for chemical processing and wastewater treatment.

Yes, PP FRP Blowers are resistant to UV radiation and moisture, making them suitable for outdoor installations.

PP FRP Blowers require minimal maintenance. Regular inspections and cleaning of the impeller and housing are usually sufficient to ensure optimal performance.

Yes, PP FRP Blowers can be customized in terms of size, airflow capacity, and pressure settings to meet specific industrial requirements.