Filter fabrics are essential components in various industrial filtration systems, designed to separate solids from liquids or gases efficiently. These fabrics are made from high-quality materials like polyester, polypropylene, or nylon, ensuring durability and resistance to harsh chemical and thermal conditions. They are widely used in industries such as mining, food processing, pharmaceuticals, and wastewater treatment.

The versatility of filter fabrics allows them to be customized for specific applications, ensuring optimal filtration performance. Whether it's for fine particle retention, high-temperature resistance, or chemical compatibility, filter fabrics provide reliable and consistent results, making them a critical part of modern filtration systems.

How It Works

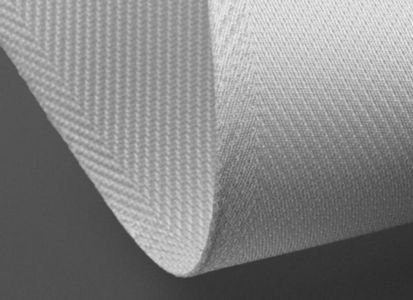

Filter fabrics work by allowing liquids or gases to pass through their porous structure while trapping solid particles. The fabric's weave and material determine the size of particles it can filter, ensuring efficient separation. The filtered solids accumulate on the fabric's surface, forming a filter cake that can be easily removed or processed further.

In many applications, filter fabrics are integrated into filtration systems like belt filters, vacuum filters, or pressure filters. These systems enhance the fabric's performance by applying pressure or vacuum to increase filtration efficiency. The choice of fabric material and weave pattern is critical to achieving the desired filtration results.

Key Features & Advantages

High Efficiency

Filter fabrics provide excellent particle retention and separation efficiency, ensuring clean filtrate and minimal residue.

Durability

Made from robust materials, filter fabrics are resistant to wear, tear, and chemical degradation, ensuring long service life.

Customizable

Filter fabrics can be tailored to specific applications, including weave patterns, material types, and pore sizes.

Versatility

Suitable for a wide range of industries, including mining, food processing, pharmaceuticals, and wastewater treatment.

Applications

- Mining and Mineral Processing

- Food and Beverage Industry

- Pharmaceutical Manufacturing

- Wastewater Treatment

- Chemical Processing

- Oil and Gas Filtration

Why Choose Filter Fabrics?

Filter fabrics are the ideal choice for industries requiring reliable and efficient solid-liquid or solid-gas separation. Their high durability, customizable design, and versatility make them suitable for a wide range of applications. With excellent particle retention and resistance to harsh conditions, filter fabrics ensure consistent performance and reduced operational costs, making them a cost-effective solution for industrial filtration needs.

Frequently Asked Questions

Filter fabrics are typically made from materials like polyester, polypropylene, nylon, or PTFE, depending on the application's requirements.

Yes, certain filter fabrics are designed to withstand high temperatures, making them suitable for applications like thermal processing or hot gas filtration.

The choice depends on factors like particle size, chemical compatibility, temperature resistance, and filtration efficiency. Consulting with a filtration expert is recommended.

Yes, many filter fabrics are designed for multiple uses and can be cleaned or regenerated, depending on the application.

Filter fabrics are widely used in industries like mining, food processing, pharmaceuticals, wastewater treatment, and chemical processing.